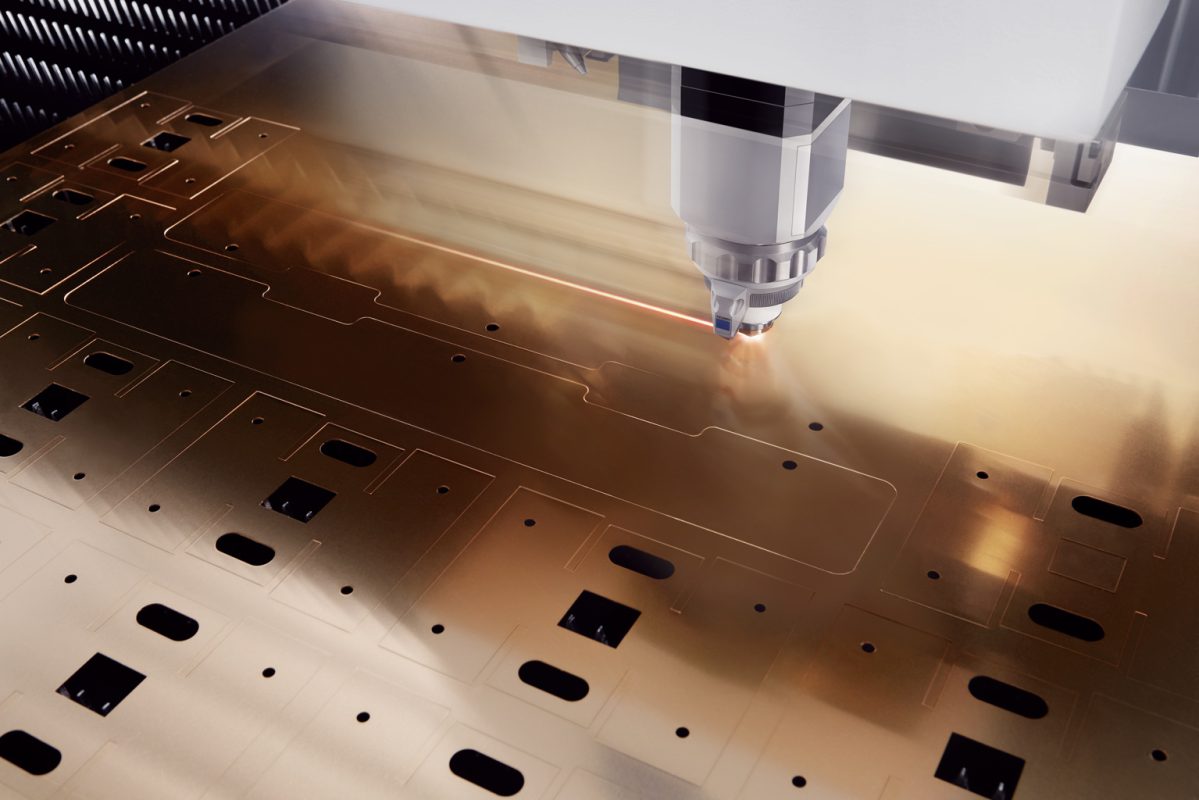

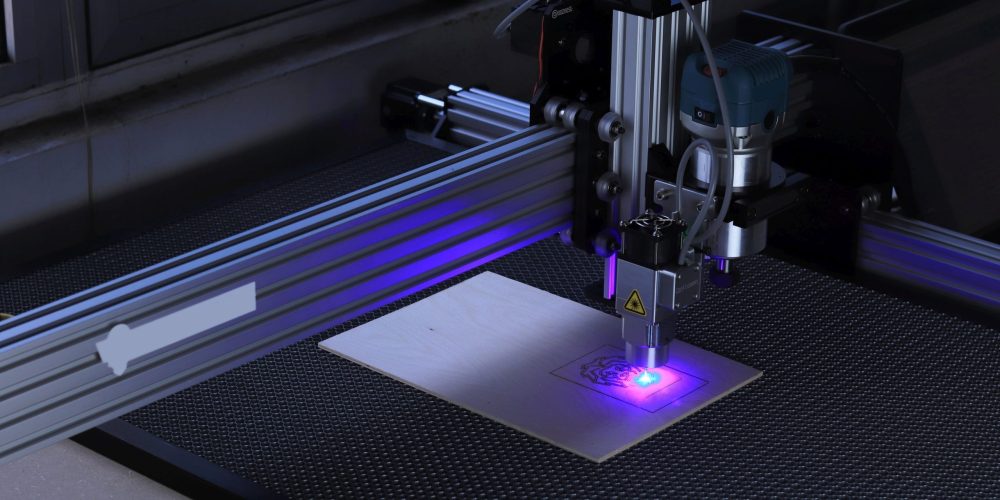

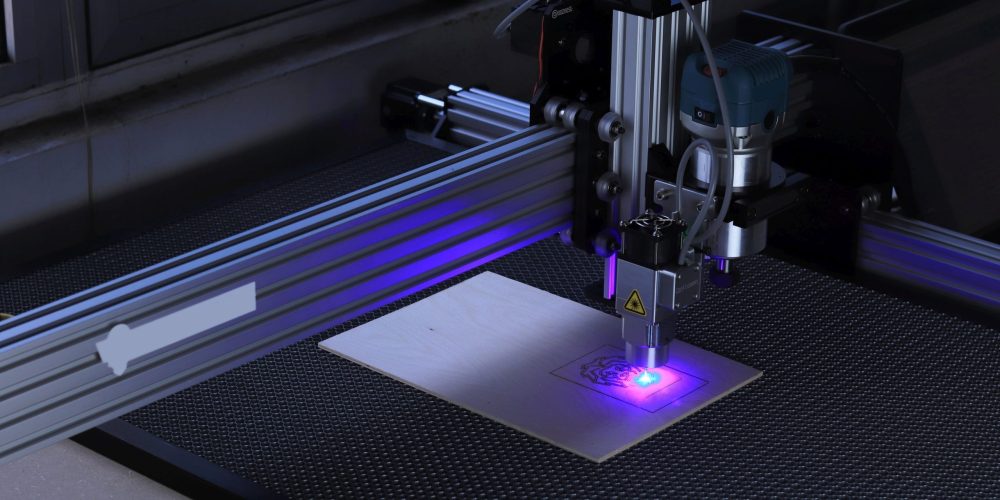

Laser processing of materials is something we specialize in. Thanks to the modern and innovative technology we use, we can guarantee the highest quality services and cost optimization. We provide comprehensive service for the order and satisfaction with its execution.

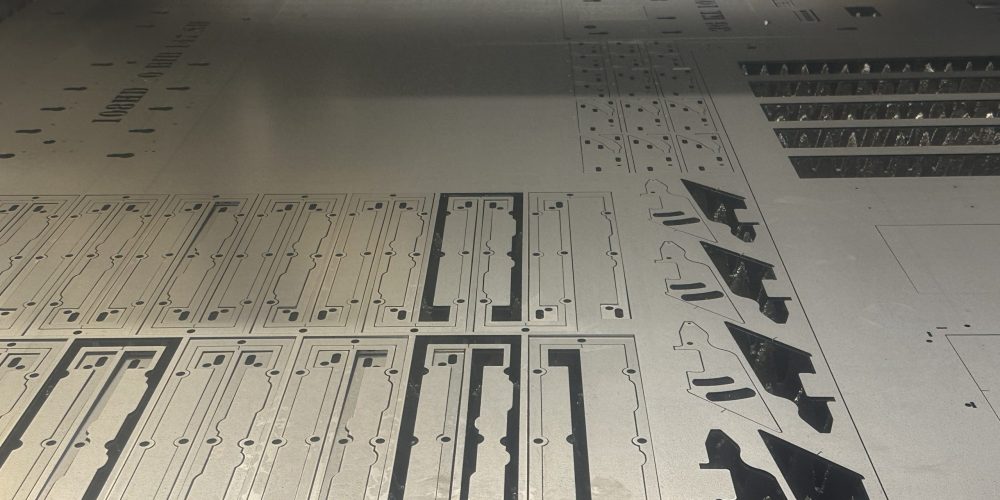

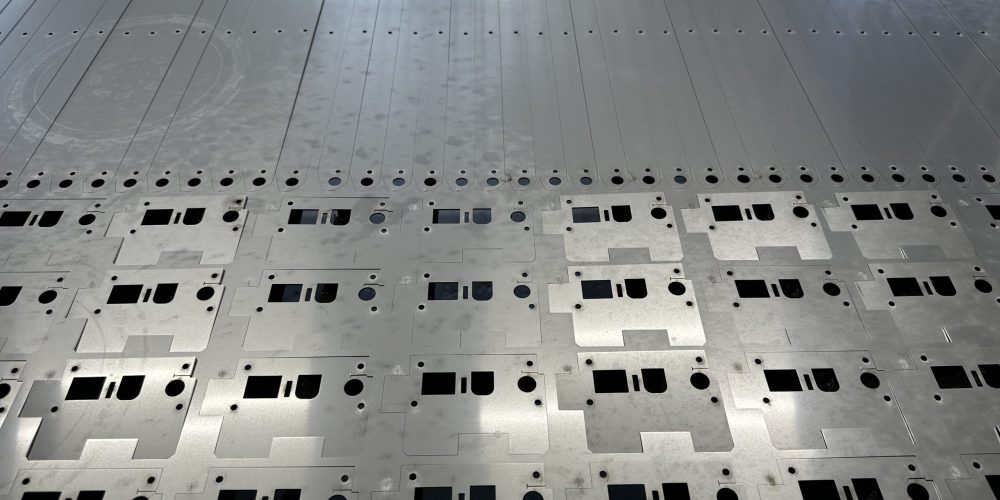

The most important advantage of this type of material processing is its versatility and freedom of operation and shaping of the cut elements. Thanks to this, we can create almost any shape and detail with the greatest precision and detail.

Our projects

Laser processing of materials is something we specialize in. Thanks to the modern and innovative technology we use, we can guarantee the highest quality services and cost optimization. We provide comprehensive service for the order and satisfaction with its execution.

The most important advantage of this type of material processing is its versatility and freedom of operation and shaping of the cut elements. Thanks to this, we can create almost any shape and detail with the greatest precision and detail.

Advantages of laser cutting

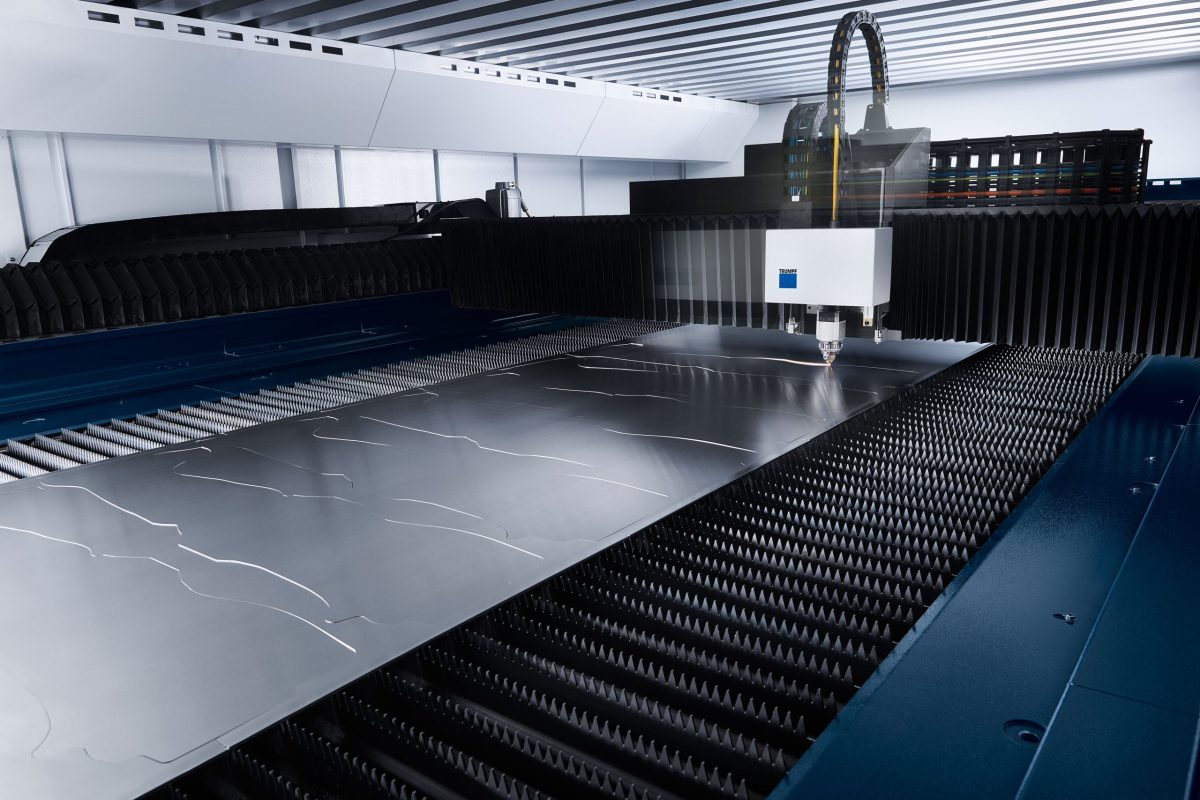

Fast implementation time

We have a large machine park with the latest technology, thanks to which we complete orders as quickly as possible

Precision

Our laser cutting machines comply with ISO standards

Finishing

Laser-cut elements often do not require post-processing; we can provide such a service at the customer’s request

Material selection

Laser cutting services are used in many industries. Due to the precision, laser cutting can be performed on materials such as: sheet metal, steel, stainless steel, metal, non-ferrous metals, plastics and many others.

Laser cutting is one of the processing methods that involves thermal separation of the material. The laser beam penetrates the processed material until it melts or completely evaporates, creating the desired element. Laser cutting is a non-contact process that eliminates deformations or mechanical damage to the cut surface. Its effectiveness means that in many cases post-processing of the element is unnecessary. The uniqueness of this process also results from the fact that no other technology allows cutting so many different types of materials, and the high precision of the machines allows you to create very detailed geometries.