Metal-Max – Metal Grinding and Polishing in Niepołomice – Quality and Precision

We provide professional metal grinding and polishing services tailored to our clients’ individual needs. Using advanced technologies and precision tools, we achieve perfectly smooth and glossy surfaces. We serve customers in Niepołomice and the surrounding areas, offering services for steel, aluminum, stainless steel, and other metals. Our experience and attention to detail ensure high-quality finishes and complete customer satisfaction with every project we complete.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Grinding and polishing are precise metal surface treatment processes that ensure a perfectly smooth and aesthetically pleasing finish. Grinding removes imperfections and scratches, while polishing enhances the material’s shine and visual appeal. Thanks to modern technologies, excellent results can be achieved even on the most demanding surfaces, such as stainless steel, aluminum, and other metals. These processes are essential in manufacturing components with high aesthetic and functional requirements.

Why choose Grinding and Polishing?

Perfect Surface Finish. Advanced metal grinding and polishing technologies ensure exceptionally smooth and aesthetically pleasing surfaces.

High Precision

Ideal for components requiring a flawless finish.

Versatility

Suitable for various materials, including stainless steel, aluminum, and brass.

Durability & Aesthetics

Finished elements maintain functionality while standing out with top-tier aesthetics.

Efficiency

The process minimizes imperfections, saving time and resources.

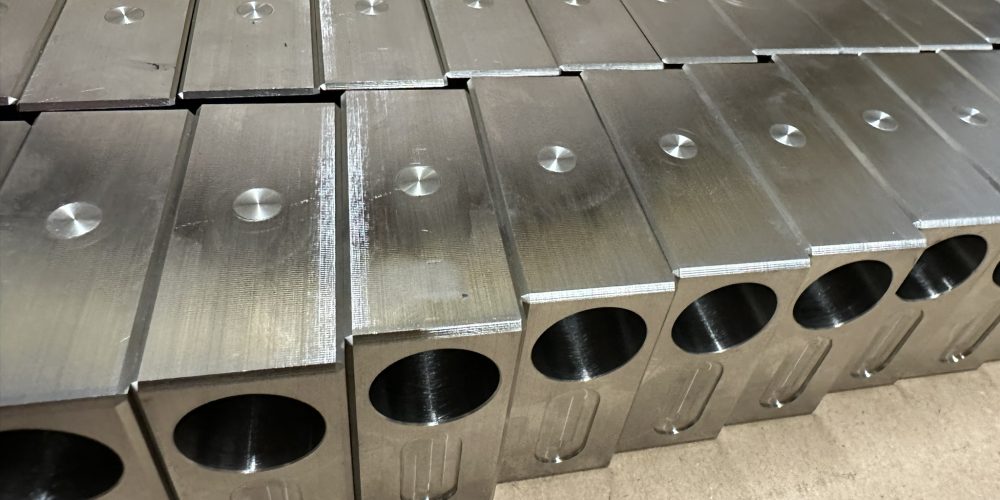

Our projects

Why Metal-Max?

Advanced Technologies

We use modern machines and tools to ensure excellent results in metal grinding and polishing.

Extensive Experience

For years, we have been delivering projects for both individual clients and businesses in Niepołomice and across Małopolska.

Personalized Approach

Every order is tailored to the unique needs of our clients, guaranteeing top-quality service.

Convenient Location

Our company is easily accessible for customers from the Kraków area and the surrounding region.

Grinding and polishing are modern solutions that combine precision and aesthetics. Thanks to advanced technologies, it is possible to achieve perfectly smooth and glossy surfaces that meet the highest quality standards. This process ensures meticulous metal finishing while minimizing the need for further processing. Suitable for both individual projects and mass production, grinding and polishing provide durability and aesthetics that meet the expectations of even the most demanding clients. It’s the perfect choice for those who value reliability and perfection.

Applications of Metal Grinding and Polishing

Grinding and polishing are widely used across various industries where surface quality and precision are essential.

Industrial Sector

Smoothing and enhancing the quality of machine parts and components.

Decorative Applications

Creating sleek, polished surfaces for ornaments and information plaques.

Automotive Industry

Finishing car parts and metal components.

Furniture Manufacturing

Processing metal elements for furniture and decorative pieces.

Energy Sector

Smoothing surfaces of energy equipment and components.

Food Industry

Treating metal machine parts used in food production to ensure hygiene and durability.

At Metal-Max Laser Technology, your projects become reality. With cutting-edge technologies, we ensure the highest quality products that meet a wide range of needs—from industrial to decorative. Our team of experts supports you at every stage of the process, from concept to finished product. You can rely on our expertise, precision, and punctuality, no matter the scale of your order.

Metal-Max Laser Technology – the leading metal processing center in Niepołomice.

Contact us now to learn how we can help bring your project to life, offering tailored solutions that ensure the highest quality.